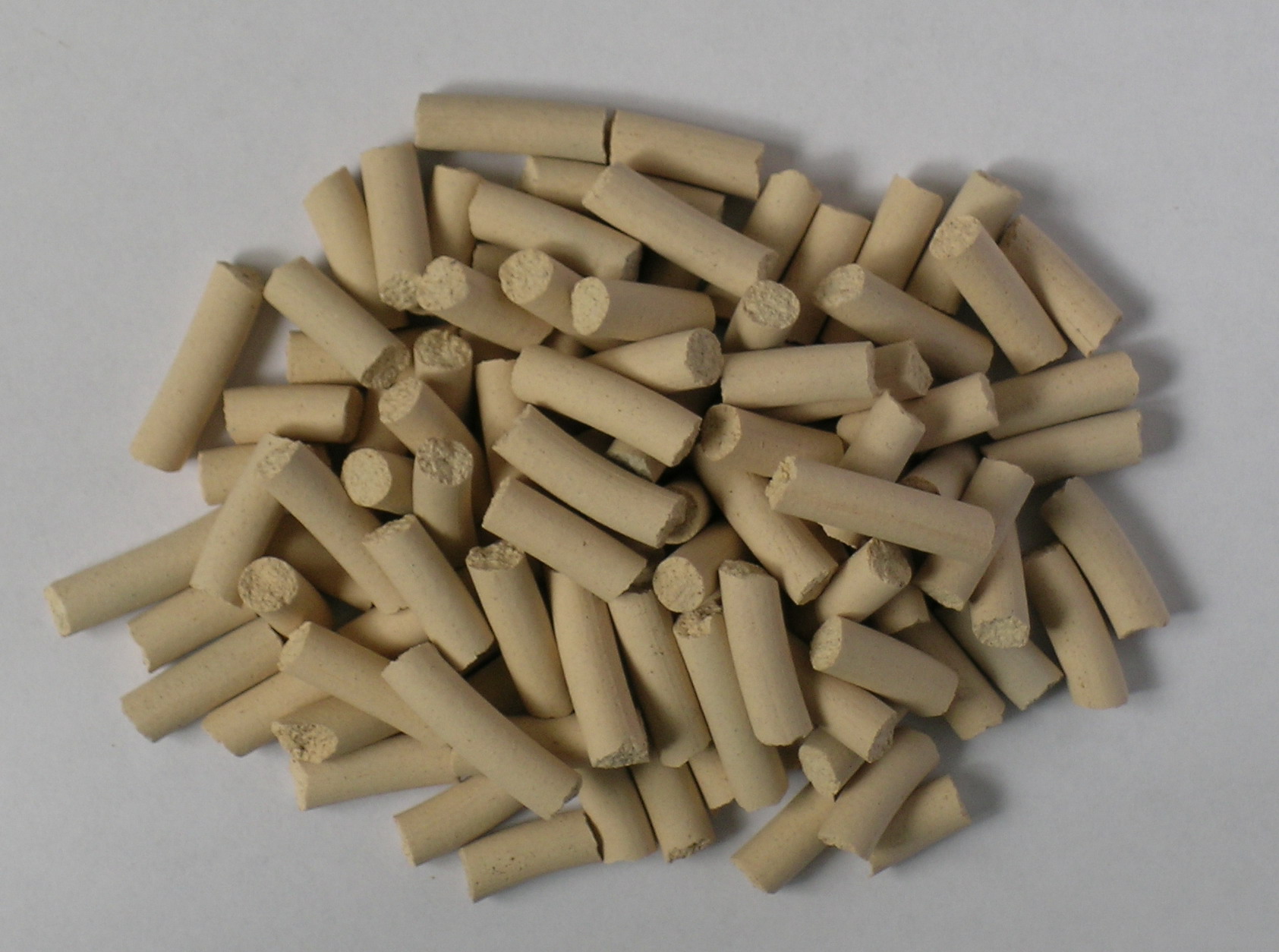

The oil and impurities carried out by the process gas through the compressor in the chemical process cause serious pollution to the transformation catalyst and equipment pipelines, resulting in a short service life of the catalyst and affecting normal production. The ET-10 high-efficiency oil absorbing agent we have developed is a brown gray cylindrical particle made by adding various active components to high-quality silicate as a carrier, and through special processes such as molding and drying. It has the characteristics of high porosity, high adsorption efficiency, large oil capacity, good mechanical strength, no adsorption of hydrogen sulfide, and no pulverization under high temperature, high pressure, and water immersion.

Detailed Introduction

The oil and impurities carried out by the process gas through the compressor in the chemical process cause serious pollution to the transformation catalyst and equipment pipelines, resulting in a short service life of the catalyst and affecting normal production. The ET-10 high-efficiency oil absorbing agent we have developed is a brown gray cylindrical particle made by adding various active components to high-quality silicate as a carrier, and through special processes such as molding and drying. It has the characteristics of high porosity, high adsorption efficiency, large oil capacity, good mechanical strength, no adsorption of hydrogen sulfide, and no pulverization under high temperature, high pressure, and water immersion.

1. Appearance, Performance, and Quality Characteristics

|

External Observation |

Bar shaped |

|

Regulations Ge (mm) |

Φ 5× (3~8) |

|

Bulk density; (kg/L) |

0.60± 0.1 |

|

Strong Degree (N/cm) |

≥ 40 |

|

Oil capacity; (%) |

≥ 30 |

2. Usage Conditions

|

Operating pressure; (Mpa) |

Normal pressure~10.0MPa |

|

Operating temperature; (℃) |

Room temperature~120 |

|

Empty Speed (h-1) |

2000~4000 |

III. Purpose

It can be widely used in various transformation processes of large, medium, and small synthetic ammonia plants, urea plants, and methanol plants that use coal as raw material.