In the synthetic ammonia industry using coal, heavy oil, and other raw materials, there are often trace chemical components with excess lone electron pairs in semi water gas, especially in low-temperature (<1000 ℃) gasification processes. Most of these compounds can cause chemical poisoning to cobalt molybdenum potassium catalysts, leading to catalyst deactivation within 7-30 days and posing a serious threat to normal production.

EB-5 type sulfur resistant antiviral agent

Wide temperature sulfur tolerant shift catalyst

Detailed Introduction

In the synthetic ammonia industry using coal, heavy oil, and other raw materials, there are often trace chemical components with excess lone electron pairs in semi water gas, especially in low-temperature (<1000 ℃) gasification processes. Most of these compounds can cause chemical poisoning to cobalt molybdenum potassium catalysts, leading to catalyst deactivation within 7-30 days and posing a serious threat to normal production.

In order to solve this problem, we first systematically studied the deactivation mechanism of Co-Mo-K sulfur tolerant shift catalysts in China, and developed the EB-5 sulfur resistant antiviral agent based on cobalt molybdenum/alumina system in 1990, which has been applied in more than 1000 industrial units.

1. Process conditions for use

■ Strong anti toxicity performance, able to fundamentally remove the toxicity of compounds with lone electron pairs through catalytic methods, thereby achieving the goal of protecting cobalt molybdenum potassium sulfur tolerant shift catalysts;

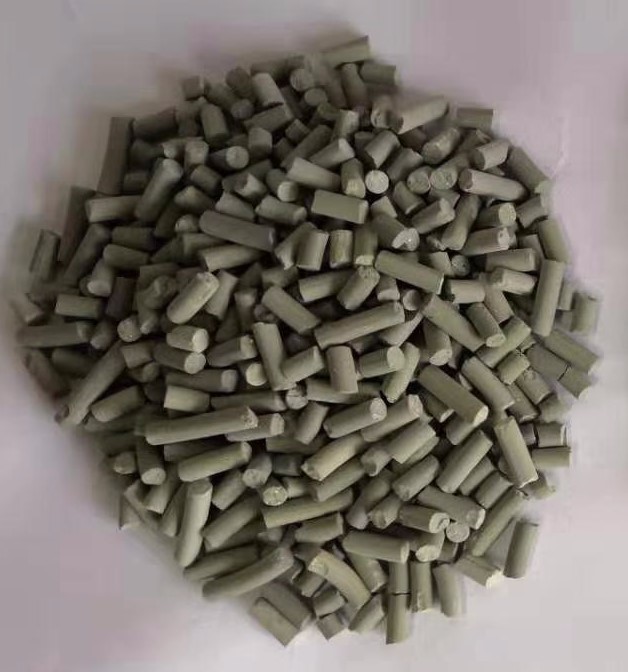

■ The appearance is spherical, with low bed resistance;

■ Use high airspeed, 5000-20000h-1;

■ Long service life, service life of anti toxic agents&service life of sulfur resistant shift catalysts;

■ Use a wide temperature range of 160 ℃ to 400 ℃.

2. Main physical properties

|

Appearance |

Spherical object pink or reddish brown |

|

Specification (mm) |

Φ 3~5 |

|

Bulk density (kg/L) |

0.7± 0.1 |

|

Average compressive strength (N/piece) |

≥ 50 |

3. Precautions

■ The loading method of this antiviral agent is the same as that of cobalt molybdenum sulfur resistant shift catalyst.

■ Can be used under normal pressure~3.0MPa conditions.

■ Before use, sulfurization is required under the same conditions as cobalt molybdenum catalysts.