In modern coal chemical industry, due to the high concentration of carbon monoxide and high water gas ratio in the gas produced by pressurized coal gasification, the adiabatic temperature rise of the transformation reaction is relatively high. The traditional multi-stage adiabatic transformation process has a long process flow, high system resistance, and greatly increases equipment investment and land occupation; The catalyst often exceeds the temperature limit and has a short service life, which affects normal production. In addition, the CO content in the gas of the calcium carbide furnace and the yellow phosphorus furnace can even reach 75-90%. Under these working conditions, the problem of using traditional transformation processes will be more serious. The high concentration of CO has raised new demands for transformation technology.

Temperature control transformation technology

Temperature control transformation technology

Detailed Introduction

In modern coal chemical industry, due to the high concentration of carbon monoxide and high water gas ratio in the gas produced by pressurized coal gasification, the adiabatic temperature rise of the transformation reaction is relatively high. The traditional multi-stage adiabatic transformation process has a long process flow, high system resistance, and greatly increases equipment investment and land occupation; The catalyst often exceeds the temperature limit and has a short service life, which affects normal production. In addition, the CO content in the gas of the calcium carbide furnace and the yellow phosphorus furnace can even reach 75-90%. Under these working conditions, the problem of using traditional transformation processes will be more serious. The high concentration of CO has raised new demands for transformation technology.

Therefore, based on the wide active temperature range of cobalt molybdenum based shift catalysts, we have developed patented technologies such as temperature controlled shift technology and temperature controlled reactors. Industrial applications have shown that this technology is a technological breakthrough in the shift process, with obvious technical advantages and promotion prospects, and can achieve good economic benefits.

1 What is temperature control transformation

Catalysts are the core of CO shift technology, and the shift process should fully utilize the various properties of catalysts. Cobalt molybdenum based shift catalysts have excellent activity at 180-480 ℃, fully utilizing the effective temperature range of the catalyst to enable the shift system to not only complete CO shift function, but also have gas purification function. For example, using the high-temperature hydrogenation performance of the catalyst to convert complex organic sulfur in the gas that is difficult to remove in the later process into hydrogen sulfide that is easy to remove is beneficial for gas purification in the later process.

The CO shift reaction is an exothermic reaction, and the equilibrium constant decreases with increasing temperature. Thermodynamically, low temperature is beneficial for reducing the CO concentration at the outlet of the shift reaction. By lowering the reaction temperature at the shift terminal, the CO concentration can be reduced. On the other hand, in terms of reaction kinetics, as the temperature increases, the rate constant of the transformation reaction increases and the reaction rate accelerates, requiring less catalyst to achieve the same transformation rate at high temperatures.

Therefore, for CO conversion, both thermodynamic and kinetic characteristics should be taken into account, and appropriate reaction temperatures should be selected at different stages of the reaction. This can not only reduce the amount of catalyst and equipment volume, but also control the outlet CO concentration, simplify the process, achieve the goal of reducing equipment investment and energy consumption.

2 Temperature control transformation technology

2.1 Temperature controlled variable reactor

(1) Temperature controlled converter

The reactor adopts a professional radial distribution flow field design to ensure uniform gas distribution inside the reactor;

To achieve rapid and sufficient heat transfer through precise hydrodynamic calculations;

Through accurate thermodynamic and kinetic calculations, the reasonable distribution of reaction temperature zones can fully utilize the various functions of catalysts.

The catalyst self dumping channel is smooth and easy to load and unload;

Reasonable selection of pressure bearing components for the reactor to avoid stress cracking and reactor failure;

The control of the reaction temperature zone is precise, and the heat exchange tube bundle should be able to expand and contract freely, with self stress compensation. A reasonable heat exchange tube bundle structure should be applied to fully absorb and eliminate thermal stress.

(2) Self heating purification furnace

Replace the pre transformation detoxification tank, feed separator, and crude gas preheater to completely solve the problem of easy blockage of heat exchange equipment.

(3) Multi stage internal cooling and temperature control converter

We have developed a multi-stage internal cooling axial temperature control transformation furnace and process technology. In a process atmosphere with a lower water to gas ratio, the transformation reaction heat is directly sprayed into the furnace for vaporization and cooling, and converted into steam. The thermal efficiency of the reactor system is extremely high. Not only does it lower the inlet temperature of the lower bed layer, but it also achieves the goal of replacing most of the external water vapor with water spray. Even under high CO concentration atmosphere, the transformation reaction is still mild and controllable, and there is no possibility of overheating. The system can recover and utilize low-grade heat from the transformation system through water as a carrier. To achieve the goal of simplifying processes, saving energy, and reducing investment.

2.2 Catalysts and Purifiers Suitable for Temperature Controlled Transformation

Excellent wide temperature activity

High conversion rate of organic sulfur

High mechanical strength and good fluidity

Good thermal stability

Resistant to different partial pressures of water vapor

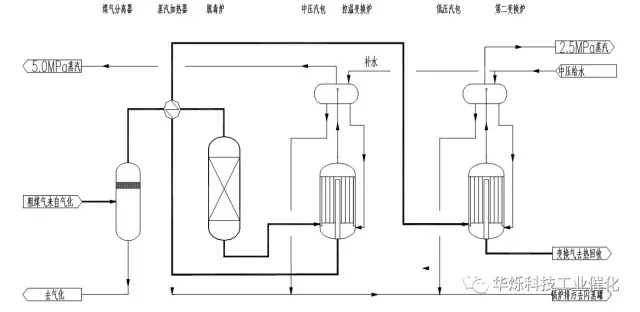

2.3 Temperature Control Transformation Process

Suitable for powder coal gasification transformation process;

Industrial application performance of temperature control transformation

The second phase project of Xinjiang Tianye adopts temperature control transformation technology for the production of 200000 tons of ethylene glycol and 180000 tons of 1,4-butanediol from calcium carbide furnace gas. In response to the gas conditions and working conditions requirements of the enterprise, the above two types of temperature control transformation furnaces were combined and used in the design. After being put into operation, significant results were achieved, and the system achieved continuous full load stable operation, with mild and controllable reaction temperature, and dual functions of transformation and purification, fully meeting the requirements of various design indicators.

Table 1 Operating Data of Temperature Control Converter

|

Project |

Tianye Phase I |

Tianye Phase II |

|

Furnace temperature (℃) |

198 |

195 |

|

outlet temperature (℃) |

217.4 |

211.6 |

|

Imported CO content (%) |

74.0 |

82.0 |

|

Export CO content (%) |

31.5 |

15.2 |

|

Resistance (kPa) |

10 |

6 |

|

by-product steam (kg/h) |

2740( 2.1MPa ) |

3000 |

|

Unsaturated hydrocarbon conversion rate% |

92.3 |

99.6 |

|

Organic sulfur conversion rate% |

93.2 |

96.5 |

Performance Table:

Xinjiang Tianye has 2 units, Huaihe Chemical has 2 units, Xinjiang Parafi has 1 unit, Sichuan Maoxian Xin New Energy has 1 unit, Xinjiang Shengxiong has 2 units, Sanning Chemical has 1 unit, and Jinmei Zhongneng has 1 unit.

4 Temperature Control Conversion Equipment Manufacturing Team‐ — Jiangsu Puge Machinery Co., Ltd.

Jiangsu Puge Machinery Co., Ltd. has A1 and A2 level pressure vessel design and manufacturing licenses issued by the State Administration of Quality Supervision, Inspection and Quarantine, as well as ASME manufacturing license (U-stamp) issued by the American Society of Mechanical Engineers. It has ISO9001:2008 quality system management certification, China Classification Society quality management system certification, and certifications from classification societies such as Japan, France, the United Kingdom, and South Korea, and has rich European standard manufacturing performance. The company has exquisite manufacturing technology, strong planning execution ability, complete testing methods, and a sound quality assurance system. It enjoys a good reputation in industries such as petrochemicals, coal chemicals, fertilizers, marine engineering, metallurgy, and pharmaceuticals both domestically and internationally.

For many years, the company has been committed to the development and research of new technologies and equipment in the field of coal chemical industry. It has successfully manufactured various core equipment for coal chemical pressure vessels, such as high-pressure and high-temperature converters, hydrogenation reactors, synthesis reactors, isothermal reactors, low-temperature scrubbers, MTO fluidized bed reactors, and high-efficiency heat exchange equipment. The company's equipment processing capability: cold rolled sheet 180mm, hot rolled sheet 250mm; non-destructive testing probe depth 250mm; lifting capacity of 250 tons.

The company has independently designed and completed specialized machining fixtures, equipment manufacturing assembly fixtures, radial distributor stamping fixtures, and other specialized equipment for the manufacturing of temperature controlled transformation furnaces. By using a CNC machining platform, the manufacturing quality of the equipment is fundamentally guaranteed. The furnace cavity of this equipment does not use any fillers or large flange structures. Based on the company's years of manufacturing experience, the assembly of the above two structures is difficult, and human factors have a significant impact. If the equipment undergoes creep during operation, the fasteners are prone to loosen, leading to leakage. The furnace cavity of the temperature controlled transformation furnace, except for the loading and unloading ports, is welded to all other pressure parts, and non-destructive testing and pressure testing are carried out to ensure that there is no leakage. The heat exchange tubes in the equipment tube process are manufactured as a whole and undergo pressure testing one by one before assembly, effectively preventing leakage of the heat exchange tubes from the source. The connection between the pipe head and the pipe plate adopts a structure of strength welding and adhesive expansion, and helium leak detection is carried out to ensure complete isolation between the process gas and the pipe head weld.

Typical application performance

Xinjiang Tianye Group Co., Ltd., calcium carbide furnace exhaust gas, 200000 tons of ethylene glycol per year.

Anhui Jinmei Zhongneng Chemical Co., Ltd. produces gas for aerospace furnaces, with an annual output of 250000 tons of methanol.

Xinjiang Tianye Group Co., Ltd. produces 6.5MPa coal water slurry gas, 300000 tons of methanol+50000 cubic meters of hydrogen.

Hubei Sanning Chemical Co., Ltd. produces 6.5MPa coal water slurry gas and 600000 tons of coal to ethylene glycol.