The ASTPEEN series of polymer permanent antistatic agents is a professional synthetic and produced polymer polyether ester amide permanent antistatic agent by our company. This product mainly forms a unique micro conductive network structure in the polymer matrix to leak charges and achieve efficient and long-lasting anti-static function. Unlike traditional anti-static agents, the anti-static performance of this product does not rely on migration to the surface of the product, nor does it depend almost on external temperature and humidity. Therefore, it has outstanding advantages such as long-lasting effect, no influence from wiping or washing, no impact on product transparency and mechanical properties. After adding ASTPEEN polymer permanent antistatic agent, the surface resistance can reach 10E6-12Ω Special anti-static performance requirements can be made into 10E5Ω Below, a conductive polymer is formed.

(1)Product FeaturesThe following are:

1、 Forever efficient: The anti-static performance will not deteriorate over time, surface wiping, or solvent cleaning, and will remain effective throughout the product's lifespan.

2、 Toughening modification: It can be used alone as an elastomer to improve the impact resistance (toughness) of the matrix material.

3、 Stable performance: Meets strict processing temperatures and methods, almost unaffected by external environmental factors such as temperature/humidity and wear.

4、 The impact on mechanical properties is minimal: it has little effect on the mechanical strength, heat resistance, and processing flowability of the matrix material.

5、 Good compatibility: It has good compatibility, and different types of anti-static agents correspond to almost all polymer materials, which are not easy to precipitate and do not affect subsequent printing, spraying or bonding processes.

6、 Convenient color matching: It can fully meet the needs of color matching.

7、 Excellent Transparency: The addition of corresponding anti-static agents has minimal impact on the transparency of the matrix resin, making it particularly suitable for applications that require high transparency.

(II) ASTPEEN series polymer permanent antistatic agent models and their application scope

|

Model |

Appearance |

Surface resistance |

Hardness |

Melting point |

Recommended materials and processes |

|

ASTPEEN100 |

|

≤ E6Ω |

80A |

130/150℃ |

1. Directly used in soft transparent materials such as TPU, PVC, TPE, POE, EVA, extrusion, injection molding, blow molding, and foaming 2. Used for extrusion (sheet), injection molding and blow molding (film) and foaming of PP, LLDPE, LDPE, HDPE |

|

ASTPEEN200 |

|

≤ E6Ω |

45D |

85℃ |

Recommended for extrusion and injection molding of PBT, TPEE, TPU, ABS, etc |

|

ASTPEEN300 |

|

≤ E6Ω |

95A |

190℃ |

Recommended for blown film of PA and its elastomers PP, PE, and transparent materials of ABS, PMMA |

|

ASTPEEN301 |

|

≤ E7Ω |

63D |

215℃ |

Recommended for injection molding, blown film of PA, ABS, PP, HDPE, PC, PET, PPO \ PPS \ PEEK, high-temperature nylon, etc |

|

ASTPEEN310 |

|

≤ E6Ω |

95A |

180℃ |

Recommended for injection molding of thermally unstable products such as POM, as well as PA, ABS, ASA |

|

ASTPEEN600 |

|

≤ E6Ω |

95A |

200℃ |

Recommended for injection molding and extrusion of sheets such as HIPS, ABS, TPEE, PC, PP, etc |

|

ASTPEEN800 |

|

≤ E6Ω |

70A |

150/170℃ |

Recommended for use in transparent materials such as TPU, PVC, TPE, ABS, POE, SBS, ASA, PP, etc |

|

ASTPEEN806 |

|

≤ E6Ω |

50D |

200℃ |

Recommended for use in materials with high processing temperatures and surface hardness requirements such as PC, ABS, PBT, PET, TPEE, etc., for extrusion (board, sheet), injection molding, molding and other processes |

|

ASTPEEN8800 series |

|

≤ E9Ω |

95A |

180℃ |

Recommended for transparent materials such as GPPS (8801), ABS (8802), PMMA (8805), PC/PET (8808), PP/PE (8818), etc

|

|

ASTPEEN900 series |

|

E6-11Ω |

Soluble in water and other polar solvents |

-35℃ |

1. Recommended for coating, pouring, molding processes such as latex, liquid silicone, liquid polyurethane, epoxy resin, paint, etc 2. Waterproof, alcohol and solvent scrubbing, strong adhesion, used for various surface coatings |

(Three)Typical substrates that can be selectedASTPEEN series polymer permanent antistatic agentsModels and precautions

|

Raw materials |

Anti static agent model (sorted by priority) |

Add quantity (E6-9Ω) |

Precautions |

Remarks |

|

PS |

600#、316#A |

15-30% |

Need to extract particles (add about 3% compatibilizer), can extrude sheet material |

316 # A is suitable for halogen-free |

|

ABS |

200#、300#、600# |

15-30% |

Mixable injection molding, squeezable sheet material |

300 # is suitable for transparency |

|

TPE |

100#、600# |

15-30% |

100 # is suitable for low hardness, 600 # is suitable for high hardness, mixable injection molding |

100 # can be made transparent |

|

TPU |

100#、600# |

15-30% |

100 # Transparent and mixable injection molding |

600 # Suitable for natural color |

|

TPEE |

100#、200#、600# |

15-30% |

100 # for low hardness |

600 # Suitable for extrusion grade |

|

Rubber |

100DRD |

15-30% |

Mixing dispersion |

|

|

EVA |

100 |

15-30% |

Blended injection molding |

|

|

PC、PC/ABS |

301、 806#、8808# |

15-30% |

Add anti hydrolysis agent, ester exchange inhibitor, and dry to control moisture content within 0.05% |

8808 # Suitable for Transparency |

|

PET |

600#、806#、8806# |

15-30% |

Add anti hydrolysis agent, ester exchange inhibitor, and dry to control moisture content within 0.05% |

8806 # Suitable for Transparency |

|

PA |

300、301、308 |

15-30% |

Blended injection molding, can draw threads |

301 # is suitable for extrusion grade, wire drawing |

|

PBT |

200#、600# |

15-30% |

Blended injection molding, can draw threads |

600 # Suitable for extrusion grade |

|

PP |

100#、600#、813 |

15-30% |

Need to extract pellets (add about 3% compatibilizer) for extruded sheets, injection molded plates, frames, etc |

600 # Suitable for extrusion grade |

|

LLDPE |

100# |

15-30% |

blown film |

|

|

LDPE、HDPE |

100#、300、301、600# |

15-30% |

Need to extract particles (add about 3% compatibilizer) |

600 # Suitable for extrusion grade |

|

PPO、PEEK、LCP |

301#、310# |

15-30% |

Need to extract particles |

Pay attention to controlling the processing temperature |

|

POM |

310# |

15-30% |

Granulation |

Can be board, rod, injection molded |

|

PMMA |

300#、8805# |

15-30% |

Granulation, mixable injection molding |

Transparent |

(Four)ASTPEEN series polymer permanent antistatic agentPerformance summary

|

Test project |

Testing method |

Type 100 |

Type 200 |

Type 300 |

Type 301 |

Type 310 |

Type 600 |

Type 800 |

Type 806 |

|

Tensile strength, 25 ℃, MPa |

GB/T 528 |

7.3 |

10.8 |

8.0 |

61.8 |

6.8 |

12.2 |

7.3 |

8.0 |

|

Elongation at break, 25 ℃,% |

GB/T 528 |

734 |

261 |

1079 |

768 |

100 |

788 |

1322 |

415 |

|

Shore hardness, 3s, HD |

GB/T 2411 |

25 |

44.5 |

25 |

62.5 |

35 |

46.5 |

25 |

31 |

|

Density, g/cm3 |

GB/T 533 |

1.226 |

1.260 |

1.065 |

1.163 |

1.188 |

1.222 |

1.241 |

1.207 |

|

Surface resistance value,Ω |

GB/T 1410 |

5.8*105 |

5.7*106 |

1.1*107 |

2.4*107 |

1.7*106 |

1.6*106 |

1.5*106 |

1.2*106 |

|

Melt flow rate, g/10min (190℃,2.16kg) |

GB- 3682 |

42.9 |

- |

26.4 |

- |

6.45 |

- |

- |

- |

|

Melt flow rate, g/10min (200 ℃, 2.16kg) |

GB- 3682 |

- |

- |

- |

- |

- |

- |

27 |

- |

|

Melt flow rate, g/10min (210 ℃, 2.16kg) |

GB- 3682 |

- |

33.96 |

- |

- |

- |

10.62 |

- |

- |

|

Melt flow rate, g/10min (220 ℃, 2.16kg) |

GB- 3682 |

- |

- |

- |

15.4 |

- |

- |

- |

0.24 |

|

Melt flow rate, g/10min (220 ℃, 5kg) |

GB- 3682 |

- |

- |

- |

- |

- |

- |

- |

1.78 |

(Five)ASTPEEN series polymer permanent antistatic agentsApplication fields

ASTPEEN polymer permanent antistatic agent is mainly used in the following fields:

Plastic processing:

Blow molded film; Injection molded profiles

Industrial tools:

Conveyor belt; Tool cart

Electronics industry:

Electronic component tray; Fixture

Cleanroom equipment:

Workbench Anti static work clothes

(Six)ASTPEEN series polymer permanent antistatic agentTypical application examples

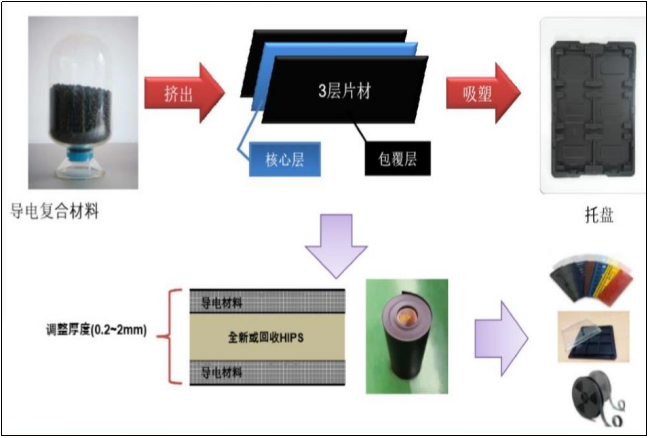

PS, ABS, and PP three-layer co extruded anti-static vacuum forming sheet materials are materials that simultaneously extrude three layers of films/sheets of different materials or functions and bond them together. They are usually designed with A-B-C or A-B-A structures, which combine the excellent properties of different materials together and solve the contradiction that a single material cannot simultaneously consider multiple properties.

The production of three-layer co extruded anti-static vacuum formed sheets is a systematic engineering that precisely combines material formulation (selection and addition of anti-static agents), equipment (co extrusion die design), and process (temperature, speed, etc.).

PS/ABS/PP Production process of vacuum formed sheet materials

|

|

Unit |

PS |

ABS |

PP |

|

|

Barrel temperature |

Feeding section |

℃ |

150-170 |

170-190 |

180-210 |

|

Compression segment |

℃ |

160-180 |

180-200 |

190-230 |

|

|

Measurement section |

℃ |

170-190 |

190-210 |

200-230 |

|

|

Melting value |

℃ |

200 |

210 |

220 |

|

|

Screw speed |

RPM |

80-450 |

|||

|

Operating current |

A |

100-240A |

|||

|

Operating pressure |

Mpa |

3-25 |

|||

|

Feeding speed |

RPM |

2-40 |

|||

The above table is a reference for single material extrusion. Three layer co extrusion requires setting separate temperatures for each independent extruder layer. The setting of barrel temperature does not have a fixed optimal solution, it is a dynamic adjustment process based on theory, combined with equipment, materials, and actual phenomena.

It is recommended to set the initial temperature based on the recommended values of the specific grade of resin and anti-static masterbatch you are using. After co extrusion, carefully observe the appearance and layering of the sheet, and adjust the temperature of each extruder (especially the metering section) and die slightly until a smooth surface, uniform thickness, and well bonded interlayer sheet is obtained.

|

Application example: |

On site pictures: |

|

|

|